Cemented Carbide Inserts Manufacturing Process

With high accuracy, high reliability under the premise of cemented carbide inserts have been global widely used to enhance productivity. Sort according to different applications, cemented carbide inserts for wood cutting tools, clamping blade, milling and turning inserts.

Cemented carbide inserts manufacturing process:

Cemented carbide inserts manufacturing process unlike casting material or steel as melted by the ore is injected into the mold after forming, or by forging, but will reach only above 3000 ℃ molten carbide powder (tungsten carbide powder, titanium carbide powder, tantalum carbide powder) is heated to more than a thousand degrees Celsius it sintered. Cobalt powder as a binding agent for the combination of such carbides more firmly. Affinity interaction between carbide and cobalt powder under the action of high temperature, high pressure, will be enhanced, thus gradually forming, this phenomenon is called sintering. Because of the use of a powder, so this method is called the powder metallurgy method.

|

|

|

|

| Fine material of a particle size of a few microns | W powders and C powders were mixed with a ball mill | The mixed powder of W powders and C powder for carbonization to prepare a WC powder | WC powder that has been carbonized |

|

|

|

|

| WC powder and Co powder, adding lubricant | Inserts forming | Formed inserts ingots |

The mass fraction of the respective components of the cemented carbide inserts according to the cemented carbide inserts manufacturing process of the different, not the same, the performance of the manufacture of cemented carbide inserts.

| Grades | HardnessHRA | Bending strength/(kgf/㎜2) | ω(w) | ω(Co) | ω(Ti) | ω(Ta) | ω(C) |

| P10 | >91 | >90 | 50%~8% | 4%~9% | 8%~20% | 0%~20% | 7%~10% |

| P20 | >90 | >110 | 60%~83% | 5%~10% | 5%~15% | 0%~15% | 6%~9% |

| M10 | >91 | >100 | 70%~86% | 4%~9% | 3%~11% | 0%~11% | 6%~8% |

| M20 | >90 | >110 | 70%~86% | 5%~11% | 2%~10% | 0%~10% | 5%~8% |

| K10 | >90.5 | >120 | 84%~90% | 4%~7% | 0%~1% | 0%~2% | 5%~6% |

| K20 | >89 | >140 | 83%~89% | 5%~8% | 0%~1% | 0%~2% | 5%~6% |

Form after sintering. Here for the whole process of the sintering step:

1) will be crushed very fine tungsten carbide powder and cobalt powder required shape pressurized, when the metal particles are connected together with each other, but the combination is not very close, as long as the point force will be slightly affected by pulverization.

2) the block powder particles already formed as the temperature increases, the degree of the connection gradually strengthen the binding of the particles in the 700-800 ℃ fragility, the voids between the particles are still many, everywhere. These voids called voids.

|

|

|

|

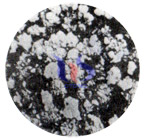

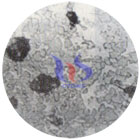

| The voids between the particles everywhere | The gap decrease between the particles | Gap further reduce | Cemented carbide inserts finished and their organizations |

3) Heating the temperature is increased to 900 ~ 1000 ℃, the decrease in the gap between the particles, was the linear portion of the black almost disappeared, the black portion of only bulk.

4) The temperature is slowly approaching 1100 to 1300 ° C (i.e., the usual sintering temperature), the void further reduce the binding between the particles becomes more robust.

|

| After heating the particles are bonded to each other, the void is gradually filled, |

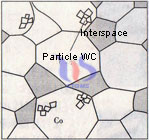

5) Upon completion of the sintering step, the tungsten carbide particles in the blades are small polygons, around which can be seen in the white substance, that is cobalt. The sintering completed blades organizations in cobalt for the base, covered with a tungsten carbide particles. The particle size, shape and the thickness of the cobalt layer is different, the nature of the cemented carbide inserts are also very different.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com