Cemented Carbide Multifork Drills

Cemented carbide multifork drills introduction

Cemented carbide multifork drills formerly known as Ni Zhifu drills, the chinese people Mr.Nizhifu invented in 1953, after his own initiative, to be renamed as "drilling", and combine the masses to participate in the meaning of improvement and perfection. 953, after his own initiative, to be renamed as "drilling", and combine the masses to participate in the meaning of improvement and perfection.The English translation is "Multifork Drill". Cemented carbide multifork drills have certain influences in the international community.

Cemented carbide multifork drills are reasonable grinding and created a new problem for ordinary twist drills type and production practice, drill-type continuous improvement, innovation, and the formation of a new set of drill-type type spectrum. It combines various characteristics grinding method ordinary twist drill grinding into a group drill is a highly effective twist drill.

Cemented carbide multifork drills depend on the application, the form of a variety of grinding, drilling form processing different materials, such as basic cemented carbide multifork drills, drilling cast iron multifork drills, drill pure copper multifork drills, drill rough multifork drills etc..

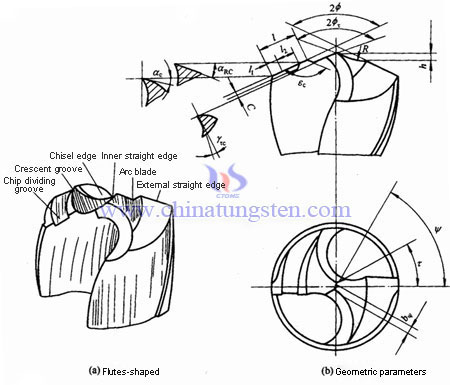

Basic multifork drills can be used to process all kinds of steel material used widely. The geometry multifork drills cutting part of the fundamental groups compared with the ordinary twist drills (medium basic multifork drills, for example), have the following characteristics:

(1) Cutting edge to form a three-point, seven blade. Each main cutting the drill type sharpening into three sections, that is, outside the straight edge, arc edge and within the straight edge, both sides were seven blade (with chisel). This segmented blade-shaped structure of the geometric parameters of the various parts of the drill can be controlled separately and more reasonable. Compared with ordinary twist drill, drilling straight blade rake angle increase is small; arc blade rake angle average growth of 10 °; within the straight edge at an average increase of 25 °; chisel at the increase of 4 ° to 6 °. So the average drilling anterior horn increased significantly, so drilling sharp edge, good cutting performance.

Arc blade and outside the straight edge of the intersection to form a new addition to the original drill tip drill tip drill so the group has a "tri-tip". The structure of the tri-tip drill centering and guiding performance is significantly enhanced.

(2) Chisel low, narrow, pointed. Group drilling center high point H = 0.03 * drill diameter, the length of the chisel edge is only the grinding before 1/4 to 1/6. Further sharpened grind months alveolar (behind the arc edge), so that has been grinding narrow chisel. This low, narrow, sharp chisel edge so that the axial resistance decreased significantly, and to enhance the centering performance.

(3) Crumb structure. The segmented structure of the main cutting edge so that the chip Sectional narrowed. Drill diameter is larger, outer straight edge on one side and then grind points flute, or staggered slot milled on both sides to fully improve the chip curling, broken and discharge effect.

This shows that the fundamental multifork drills is made up by three sharp, seven blade, month alveolar, points flute and short chisel.

| Basic multifork drill blade shapes and geometric parameters |

|

Multifork drills have seven main cutting edges, tri-tip shape. Grind larger apex angle to the outer edge of the formation of the outer straight edge, the middle grind concave arc edge, discrepancies in the actual grinding chisel edge is formed within the straight edge. Larger diameter drill bit to open on the side of the outer edge of one or two flutes. Therefore, the characteristics of the drilling blade-shaped: seven blades sharp at the head of the tri-tip, crescent arc slot points on both sides, the side of the outer edge open flute low cross sharpening narrow and sharp.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com